Landing

Gear System Presentation

The A320 family aircraft are equipped with dual wheel main landing gear, which retracts inboard.

Gears

and main doors are hydraulically operated and electrically controlled by two

computers named Landing Gear Control and Interface Units (LGCIU).

The

doors which are fitted to the landing gear struts are operated mechanically by

the gear.

A

dual wheel nose landing gear retracts forward.

The

Nose Landing Gear (NLG) has an oleo-pneumatic shock absorber.

The

nose gear main doors operate hydraulically.

The

fixed doors (aft doors and leg doors) are operated by the gear.

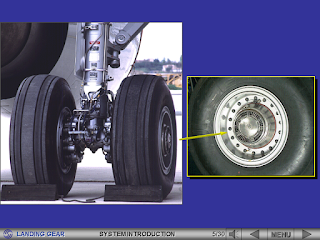

The wheels of the main landing gear are equipped with:

- carbon brakes for efficient braking, even at high temperature,

- an anti-skid system (A/SKID),

- an automatic braking system (AUTO/BRK),

- brake fans (optional),

- and an optional Tire Pressure Indicating System (TPIS).

The

A320 provides two braking modes:- an anti-skid system (A/SKID),

- an automatic braking system (AUTO/BRK),

- brake fans (optional),

- and an optional Tire Pressure Indicating System (TPIS).

- NORMAL braking,

- and ALTERNATE braking.

- and ALTERNATE braking.

Normal

braking is powered by the green hydraulic system.

Alternate braking, which includes the parking brake, is powered by the yellow hydraulic system.

Alternate braking, which includes the parking brake, is powered by the yellow hydraulic system.

All

braking functions (normal braking control, anti-skid control, automatic braking

and brake temperature indications) are controlled by a two channel

Braking/Steering Control Unit (BSCU).

The

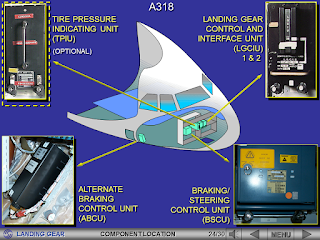

A318 also provides two braking modes:

-

NORMAL braking,

- and ALTERNATE braking.

- and ALTERNATE braking.

Normal

braking functions are controlled by the Braking/Steering Control Unit (BSCU).

Alternate

braking is controlled by the Alternate Braking Control Unit (ABCU) and receives

anti-skid orders from the BSCU.

The

nose landing gear is equipped with nose wheel steering.

It is

hydraulically operated by the green hydraulic system and electrically

controlled by the BSCU.

On

the A318, the nose landing gear is hydraulically operated by the yellow

hydraulic system.

A downlock

safety pin must be installed before maintenance operations.

The

ECAM WHEEL page displays indications for the:

- main landing gear and nose landing gear.

On the A318, the ECAM page has a new configuration for the landing gear indications.

On the A318, the ECAM page has a new configuration for the landing gear indications.

...

…

- nose and main landing gear

doors,

...

…...

- brake temperature given by the temperature sensors through the BSCU.

In

the center of the ECAM WHEEL page, green and amber messages can be displayed to

provide normal and abnormal indications.

On

the A318, as the alternate braking becomes electrically controlled and thanks

to the new EIS, more information is displayed on the nose wheel steering and

braking systems.

The

ECAM WHEEL page displays the NLG and MLG tire pressures when the optional Tire

Pressure Indicating System is installed.

The

system consists of pressure sensors and a Tire Pressure Indicating Unit (TPIU).

On

the A319, A320 and A321, the position of the spoilers is displayed at the

bottom of the ECAM WHEEL page.

On

the A318, it is displayed at the top of the ECAM WHEEL page.

The

landing gear panel contains switches and indicators for:

- the LDG GEAR,

- the AUTO/BRK,

- the BRK FAN,

- and the A/SKID & N/W STRG.

- the AUTO/BRK,

- the BRK FAN,

- and the A/SKID & N/W STRG.

When

autobrake is used, selection of LO, MED or MAX is made using these pushbutton

switches.

The

anti-skid and nose wheel steering switch controls both functions. The switch is

normally left in the ON position.

The

red arrow warns the flight crew that the landing gear is not locked down when

the aircraft is in landing configuration.

The

landing gear gravity extension handle is located on the center pedestal. It

mechanically operates the doors and gear.The steering hand wheels are located on each side of the cockpit, so either pilot can taxi the aircraft. They control the nose wheel steering through the BSCU.

The rudder pedals can also be used to steer the aircraft.

The rudder pedals are located on each side of the center pedestal.

Manual braking is provided using the top of the rudder pedals.

The

parking brake handle is located on the center pedestal.Manual braking is provided using the top of the rudder pedals.

It

operates a rotary switch which electrically controls the parking brake

application.

This

gage, which measures pressures from the alternate braking system and brake

accumulator, is located on the main instrument panel.Up, down and unlock indications are associated with position indicators on the WHEEL page.

The landing gear computers are located in the forward avionics bay.

Note

that the TPIU is an option.

On

the A318, an Alternate Braking Control unit (ABCU) is added and the BSCU is

replaced.The safety valve isolates the landing gear hydraulic lines from supply pressure when the aircraft speed is greater than 260 knots.

The nose landing gear doors and each main landing gear door can be opened (and closed) independently on ground using their own ground door opening handle.

The handle located on the electrical box allows the nose wheels to be isolated from the nose wheel steering for towing purposes.

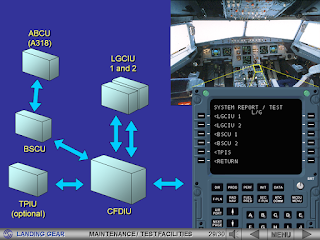

Using the MCDU (Multipurpose and Control Display Unit), you can have access to the CFDS (Centralized Fault Display System) fault messages of each landing gear system. Specific BITE tests are available as well.

The

BSCU is a dual channel computer. The BSCU BITE stores fault messages of braking

and nose wheel steering systems.

An

Alternate Braking Control Unit (ABCU) is added on the A318.

On

the MCDU SYSTEM REPORT/TEST L/G menu page, the TPIS line is always displayed,

even if the system is not fitted on the aircraft.

Using

the MCDU (Multipurpose and Control Display Unit), you can have access to the

CFDS (Centralized Fault Display System) fault messages of each landing gear

system. Specific BITE tests are available as well.

The

BSCU is a dual channel computer. The BSCU BITE stores fault messages of braking

and nose wheel steering systems.

An

Alternate Braking Control Unit (ABCU) is added on the A318.

On

the MCDU SYSTEM REPORT/TEST L/G menu page, the TPIS line is always displayed,

even if the system is not fitted on the aircraft.

When you work on the landing gear system, make sure that you obey all the AMM safety procedures. This will prevent injury to persons and/or damage to the aircraft. Here is an overview of main safety precautions relative to the landing gear system.

When you perform any maintenance task, make sure that all circuits are isolated. Unwanted electrical or hydraulic power can be dangerous.

Make sure that the travel ranges of the landing gear and doors are clear. Movement of the landing gear and doors can cause injury and/or damage.

Make sure that the wheel chocks are in position, and the landing gear ground safety locks are installed. This prevents unwanted movement of the aircraft and landing gear.

Let the brakes and the wheels cool down before you go near the landing gear. Do not apply a liquid or gas fire extinguisher directly on a hot wheel or brake unit. This could cause an explosion.

Use only nitrogen for tire inflation. If the brakes overheat, other gases can cause an explosion.

During landing gear servicing, do not let high pressure gas get in contact with your skin. Gas bubbles in your blood can kill you.

Hi! How are you? I learn to AME in Korea. I think you learned it a lots. :)

ReplyDeleteThen i hope to know what is these pictures. Where did you got it?

Please let me know!

Do the A320 type course you will learn everything

DeleteThis comment has been removed by the author.

ReplyDeleteNice Blog.

ReplyDeleteAviation Doors by Nihva are designed for tough environment with extremely large openings. Nihva offers high quality full featured, most economic aircraft Hangar Doors in India

I really appreciate this post. Thank you so much for sharing this superb blog, this is really helped me a lot. As well as I referred extended landing gear leg , and I hope it will also help more to all.

ReplyDelete"When I was applying for a loan to purchase my building as a small business owner in a tough situation, conventional banks said they could not help me. the loan firm from mr lee sat down with me, heard my situation and decided that I was worth taking a chance on. Here we are 5 years later and I have just renewed my loan for another 7 years. I couldn’t have purchased my building without the help of the loan from mr lee and will be forever indebted to them for giving me a chance when no one else would."here is mr lee contact Email: 247officedept@gmail.com Also on whatsApp: +1-989-394-3740So I will advise anyone here looking for a loan to contact mr lee for an assistance of loan fundings.

ReplyDeletePerde modelleri

ReplyDeletesms onay

mobil ödeme bozdurma

nft nasıl alınır

ankara evden eve nakliyat

trafik sigortası

DEDEKTOR

web sitesi kurma

Aşk romanları

smm panel

ReplyDeletesmm panel

iş ilanları

İnstagram takipçi satın al

hirdavatciburada.com

beyazesyateknikservisi.com.tr

servis

tiktok jeton hilesi

Good content. You write beautiful things.

ReplyDeletehacklink

hacklink

vbet

korsan taksi

vbet

sportsbet

mrbahis

taksi

sportsbet

Success Write content success. Thanks.

ReplyDeletecanlı slot siteleri

betpark

canlı poker siteleri

deneme bonusu

kıbrıs bahis siteleri

betmatik

betturkey

This post is on your page i will follow your new content.

ReplyDeletesportsbetgiris.net

mrbahis.co

casino siteleri

mrbahis giriş

betgaranti.online

mrbahis

sportsbet giriş

sportsbet

sportsbet

dijital kartvizit

ReplyDeletereferans kimliği nedir

binance referans kodu

referans kimliği nedir

bitcoin nasıl alınır

resimli magnet

QQH

hatay

ReplyDeletekars

mardin

samsun

urfa

ADD